Do New Trucks Fail on Purpose? The Truth About Planned Obsolescence

For years, online videos have claimed that modern trucks are doomed to fail once the warranty ends. Complaints about turbochargers, thin oil, oil change intervals, plastic components, recalls and more topics fuel the idea that automakers deliberately engineer trucks that conveniently fail right when the warranty ends forcing customers to buy new trucks every few years lining the automakers pockets.

Is it true? Is this really going on?

Let’s examine key items people believe are leading to engines failing.

The Turbocharger Turnaround

Fifteen years ago, I started covering the industry and back then, the criticism on new trucks centered on turbochargers. It was right around the time, the Ford EcoBoost engine came out with its twin-turbocharger causing a lot of debate online.

Back in the 1970s and 1980s, automakers had tried turbocharged engines and they had failed spectacularly. Many people got burned financially on these purchases and the feeling of “here we go again” was very prevalent.

Even though Ford pushed hard with marketing strategies showcasing the durability of the new engine, discussing in detail this time the engine was designed as a turbocharged engine from the start and not as an afterthought like the engines from decades earlier, it didn’t matter.

The feeling was once the EcoBoost-powered F-150 was used to either tow for much of its life or driven in hot weather for extended periods, the smaller engine would be stressed to the point it would fail right around the powertrain warranty ended at 5 years or 60,000 miles.

I helped fuel this concern by writing stories on how much it cost to replace a single turbocharger, about $2,000 back in 2011, and covered the first big issue with condensation building up in the intercooler in humid areas. Owners would drill a 1/16 inch hole as a DIY fix until Ford came out with a permanent fix.

When did I write those stories? About a decade ago. The first F-150 EcoBoost came out in 2011 and while there are reports here and there about an owner replacing a turbo, the numbers don’t match up to the fear.

Today, the majority of Ford F-150’s sold are turbocharged, all truck makers have a turbocharged engine and the vast majority of SUVs on the road are turbocharged.

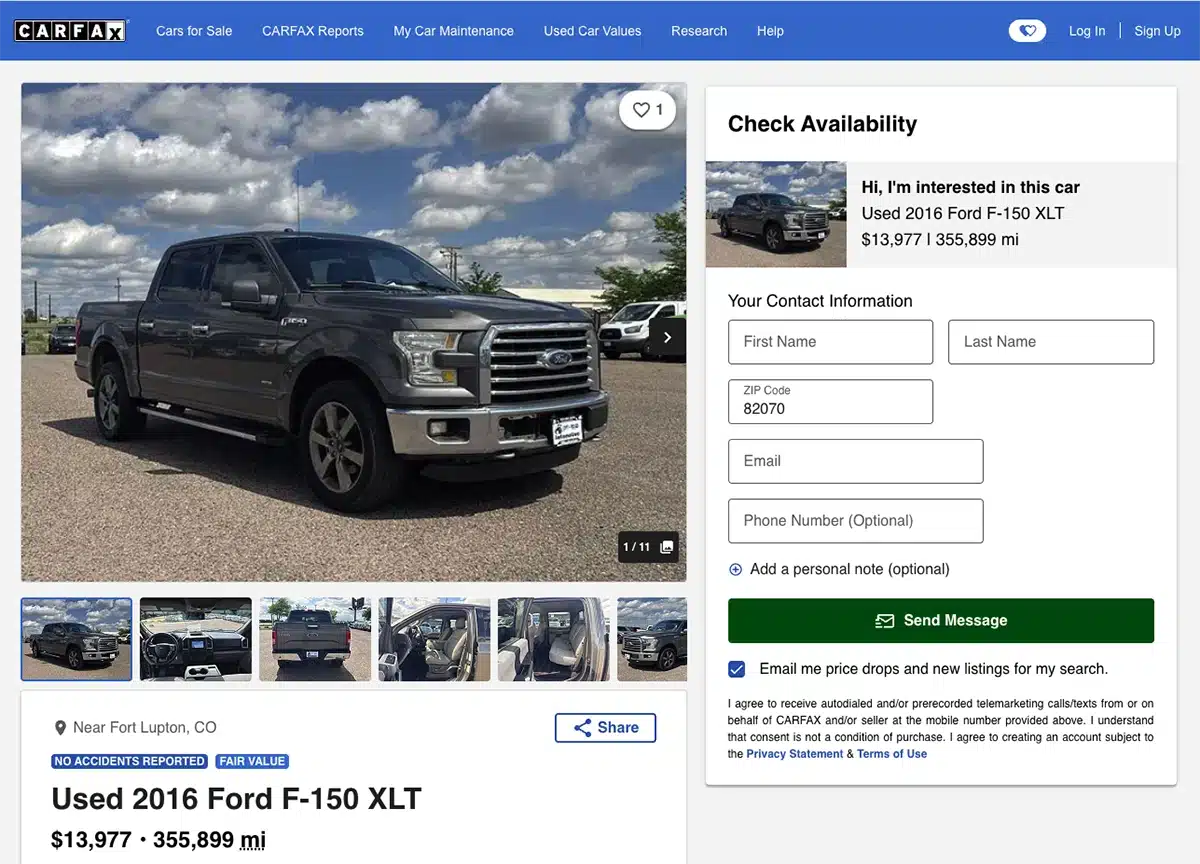

What about built to fail? If that was the case, we’d see dealership lots filled with vehicles waiting for new turbocharged engines at the 5-year mark and CarFax history reports would be filled with engine replacements. It just isn’t the case.

The Thin Oil and Oil Change Interval Debate

A new battleground has emerged around oil types and change intervals causing engines to fail. Many critics blame environmental regulations for pushing 0W-20 and 0W-40 oils, claiming they compromise durability. The claim is automakers are being forced to use the oils and the automakers don’t want to use the new oil and they certainly don’t want longer oil intervals that destroy engine life.

It is the U.S. EPA that is to blame for engines failing and automakers are adhering to this guidance leading to the planned obsolescence conspiracy!

Ok. Let’s insert a few facts here.

The EPA is an easy target for sure. I’ve read the reports going back through the last several administrations and it isn’t at all what people presume. The facts are automakers do have a say in the fuel economy standards. And many times, they have already hit the targets before the new U.S. regulations are in place because of achieving global standards first. Automakers are global companies that plan ahead in 5-10 year increments and they are already working on future standards like Euro 7 and the U.S. 2032 standards. Those standards aren’t calling for a massive jump in fuel economy, rather they are addressing reductions in NOX gases.

Second, the oil types, here in the U.S., are certified by the American Petroleum Institute and set as standard by the International Lubricant Standardization and Approval Committee. The newest one called GF-7 was “developed through industry collaboration between automakers and oil companies, is designed to improve on the existing oils out there to better protect turbocharged engines and other engines with gasoline direct injection or both,” according to our May, 2025 post.

This GF-7 oil is meant to better protect the engine and is meant to make it more durable. People miss out on the fact all the time. Thinner weight oils are designed to improve reliability, not make it worse.

The oil companies are coming up with these lighter weight oils for their largest customers – the automakers. Those automakers want the oils for better durability and fuel economy. Yes, both. Why? Car shoppers want a vehicle that lasts a long time and is good on fuel.

As far as oil change intervals are concerned, people are really skeptical about 10,000 mile intervals. This interval is way too long in their view and is destroying engines because the oil can’t possibly last that long.

The thing is automakers are moving away from pre-set mileage intervals. Instead, they are moving toward oil life indicators that analyze the oil, use mathematical equations based on the vehicle’s usage and other factors to determine when to change the oil.

The truth is the oil change interval based on mileage is not going to be a discussion point in the future. It is actually a dumb way of doing things. The truth is if you tow a lot more often, you really should change your oil more often than if you just drove around town all day. The oil life monitors do a much better job of recognizing this and dictating when to change your oil.

How could 10k oil change intervals be planned obsolescence when some brands aren’t using them anymore?

Plastics, Known Flaws, and Aftermarket Fixes

Modern engines use more plastic than ever before, from thermostat housings to intake parts.

Some failures have made headlines, such as a faulty Ram thermostat housing that was quickly corrected by the automaker—and improved upon by aftermarket suppliers with billet aluminum replacements—at a substantial increase in cost.

Transmission issues have also surfaced, with aftermarket companies stepping in to provide stronger solutions, with some claiming problems with them.

While these cases fuel suspicion of “planned obsolescence,” they often reflect short-term quality missteps rather than intentional failures.

The issue really arises when a few things happen.

First, in the case of the GM 10-speed wheel-lock up issue, a recall was issued to replace a problem that had arisen when some trucks. The problem was for those people who were affected, the truck wasn’t drivable until the parts were available and there was a delay getting the parts. This led to months of waiting forcing those customers to buy something else.

Second, in some areas, the conditions are just right for things to fail and it takes time for automakers to find out. For example, the wheel liners on the Toyota Tundra are now affixed with special fasteners. Why? There is a unique type of mud in oil fields of Canada that hardens like concrete and literally rips the mud flaps off the trucks. It took months for the service reports to work their way up to senior leadership at Toyota. Those engineers hopped on a plane to examine this mud and were shocked at what they found. They actually shipped some of it back to their proving grounds and changed the way they bolted on the wheel liners.

Similar things happen with plastics used throughout vehicles. Some shops will tell me they replace certain plastic items while others say they never do. The shops that do believe the parts are built to fail and the other shops just shake their heads when I tell them that. All about perception and not planned obsolescence.

Warranty Extensions and Recalls Raise Questions

When people tell me trucks are built to fail right at the end of the warranty period, I ask them which warranty. This causes a lot of confusion.

The natural response is the powertrain warranty, you dummy! However, this varies.

For example, I purchased a 2025 Ram 1500 RHO for a long-term review truck in January, 2025. This came with a 5 year warranty or 60,000 miles. In June, just 6 months after, Ram announced all 2026 models will come with a 100,000 mile warranty. Am I too believe Ram was able to inform all their suppliers and the suppliers suppliers to improve their quality, have their engineers redesign their trucks for better quality in just those few months when it takes years to engineer and build a new truck?

Ram isn’t alone in this. GM has done the same thing when it extended its warranty on the 2.7-liter turbocharged engine.

And diesel engines have 100,000 mile warranties and electric vehicles come with longer warranties as well.

Not to mention, how does this make sense when you have trucks for sale with 100k miles, 200k miles, 300k miles+ without major engine repair? Are those trucks just lucky?

Finally, let’s say this was happening. Automakers wouldn’t be off the hook. The NHTSA Office of Defects can still force automakers to recall trucks for engine failure beyond the warranty period. Honda is dealing with this right now with a second recall on its 3.5-liter V6 engine. It is spending millions of dollars to recall that truck.

If Honda was thinking about planned obsolescence for their V6 engine, they really screwed up, because it is costing them millions to replace them.

The Real Concern: Electronics and Wiring

While the engine itself has largely grown more reliable over the years, the real concern for truck reliability lies in electronics.

I’ve been talking about this for years and finally we are starting to see other outlets discussing it.

Today’s pickups are packed with sensors, driver-assist systems, and luxury features, all dependent on a single 12-volt battery and miles of wiring. Failures can be costly—not because parts are expensive, but because repairs often require tearing apart the vehicle. Mechanics increasingly point to sensors and wiring harnesses as the weak link, not the engines themselves.

We should have moved to a 24-volt system by now with 2 batteries running all these electronics. And we should have more research done on how to prevent mice from eating the wiring in the engine bay.

It isn’t so much planned obsolescence on those items, it is more about outside factors like mice and weather conditions playing havoc. Go ahead and store your laptop in a snow drift in negative temperatures for a few months for years on end and see how long it lasts. That’s basically what a truck is these days, a rolling computer.

Bottom Line on Planned Obsolescence

Do accountants force engineers to scale back their grand ambitions on parts? You bet. Do engineers think that means the part they are using isn’t the best quality it could be? You bet. Do statements like that get people mad online when they hear some “insider” make those statements? Absolutely.

People believe the greedy automaker is sitting on trillions of dollars and raising truck prices forcing them to never be able to afford a new truck. One such person told me, automakers were purposely killing the middle class.

The reality is if engineers had their way and no accountants were involved, truck prices would skyrocket. There has to be a balance between overengineering every part and not having a $200,000 truck. And there has to be an understanding that trucks, statistically, are lasting longer than ever and the price, adjusted for inflation, for base-level trucks hasn’t risen that much in the past 10 years. Wages have stagnated and a person’s desire to buy a certain trim level of truck has changed.

As far as planned obsolescence, there really is no way to prove one way or another. If you believe an automaker cut a corner to save a penny and that reduced quality, then you’re right. If you believe an automaker saved a penny that actually worked out to be $500k per year when multiplied by the number of vehicles involved, kept quality the same since they ran all the same testing procedures on both parts and that was a good business decision, then you are right.

For me, it is all about your perception and your frustration.

Post a Comment for "Do New Trucks Fail on Purpose? The Truth About Planned Obsolescence"

Post a Comment